In the fast-paced world of logistics and supply chain management, maximizing warehouse efficiency is more important than ever. An optimized warehouse can lead to significant cost savings, increased productivity, and a smoother operational flow. The key to achieving this efficiency lies in selecting the right storage solutions and designing an effective layout. In this blog, we’ll explore essential storage solutions and layout tips, with a special focus on how cantilever racking can transform your warehouse operations.

Understanding Warehouse Efficiency

Warehouse efficiency is defined by how well a warehouse utilizes its space, resources, and processes to store, manage, and distribute goods. Achieving optimal efficiency involves a combination of strategic storage solutions and a well-planned layout. Let's dive into how you can enhance your warehouse operations with these crucial elements.

Essential Storage Solutions for Warehouse Efficiency

- Cantilever Racking

Cantilever racking is a standout solution for warehouses that handle long, bulky, or irregularly shaped items like pipes, lumber, or metal rods. Unlike traditional racking systems, cantilever racking features arms that extend from a vertical column, allowing for unobstructed access to the stored items. This design maximizes vertical space and provides easy access, which is particularly beneficial for handling oversized goods. Cantilever racking is also highly adjustable, making it versatile for various storage needs.

- Heavy Duty Racking Systems

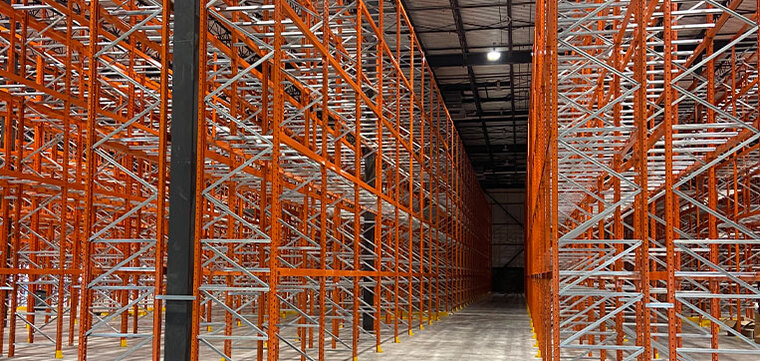

Heavy duty racking systems are vital for optimizing warehouse space and improving material handling. These systems are designed to support substantial loads and are ideal for warehouses with bulky or heavy items. Key types include:

- Selective Racking: Offers easy access to all pallets, suitable for warehouses with a high turnover rate of diverse products.

- Drive-In Racking: Ideal for high-density storage, where pallets are stored in a single block, minimizing aisle space and maximizing storage capacity.

- Push-Back Racking: Facilitates high-density storage with FIFO inventory management, perfect for warehouses with limited space and a need for efficient stock rotation.

- Static Shelving

Static shelving systems are versatile and efficient for organizing smaller items or those that require frequent access. Adjustable to various heights, static shelving helps accommodate different product types and improves accessibility. This solution is particularly useful for picking stations or areas where quick retrieval of goods is essential.

- Mezzanine Floors

Mezzanine floors are a smart way to create additional storage space without expanding your warehouse’s physical footprint. Adding a mezzanine can effectively double your storage capacity and can also be used for office space, packing stations, or overflow storage. This solution makes the most of vertical space, increasing overall warehouse efficiency.

- Wire Partitions

Wire partitions are ideal for creating secure zones or designated storage areas within a warehouse. They provide visibility and accessibility while allowing you to segment space flexibly for different uses, such as secure inventory storage or personal lockers.

Layout Tips for Enhanced Warehouse Efficiency

Zone Allocation

Efficient zone allocation is critical for optimizing warehouse operations. Position high-demand items close to picking and packing areas to reduce travel time and streamline processes.

Workflow Optimization

Design your warehouse layout to support smooth workflows. Ensure that areas for receiving, picking, packing, and shipping are well-organized and logically placed to reduce bottlenecks and redundant movements.

Contact a Warehouse Storage Solutions Specialist

Maximizing warehouse efficiency requires careful planning and the right storage solutions. By investing in effective storage systems, such as cantilever racking, and optimizing your warehouse layout, you can drive productivity, reduce costs, and enhance overall operational performance.

.png)

.png)

Leave Your Comment & Rating Below

0 Comment(s)